Phil Auto Parts

Phil FREY Auto Parts is a large-scale auto parts supply chain enterprise serving the global market. It has multiple subsidiaries and domestic and foreign trade warehouses, with tens of thousands of SKU products in stock.

Business pain points

The original ERP system for purchase, sales and inventory cannot effectively support the warehousing business. Both the delivery and receipt of goods require manual preparation of orders by sales/purchasing staff, and then the orders are sent to the warehouse via QQ for operation.

After the warehouse operations are completed, the sales/purchasing team needs to personally go to the warehouse for verification and then manually increase or decrease the inventory on the system.

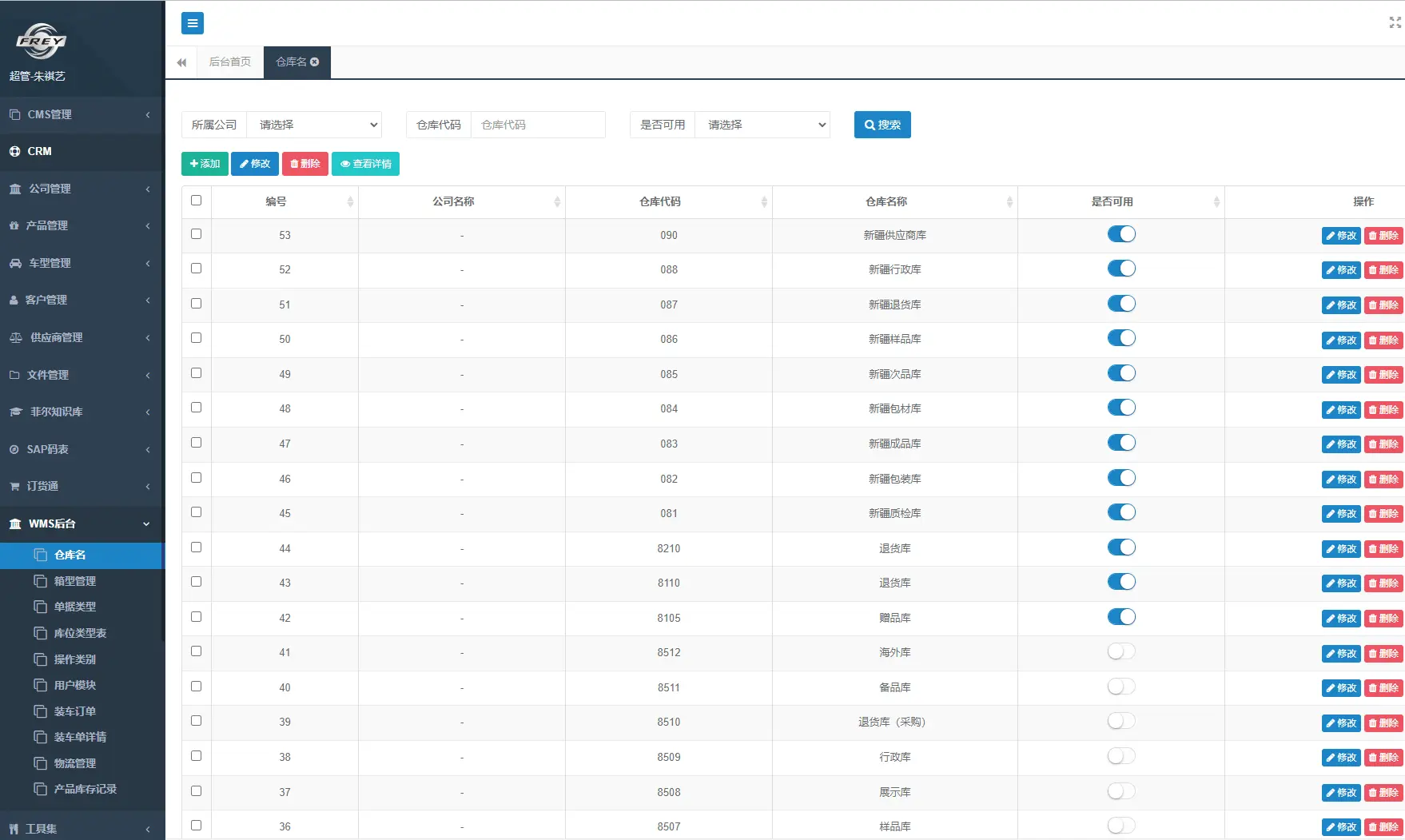

3. The inventories for foreign trade and domestic trade are mixed together and cannot be managed separately or flexibly transferred.

4. The inventory management system and the financial system are not integrated. It is necessary to submit paper business documents from the finance department, which will then be manually entered into the financial system by the finance department.

5. Labels, shipping marks, packing lists and other documents for both domestic and foreign trade all need to be made manually, which leads to low work efficiency.

Solution

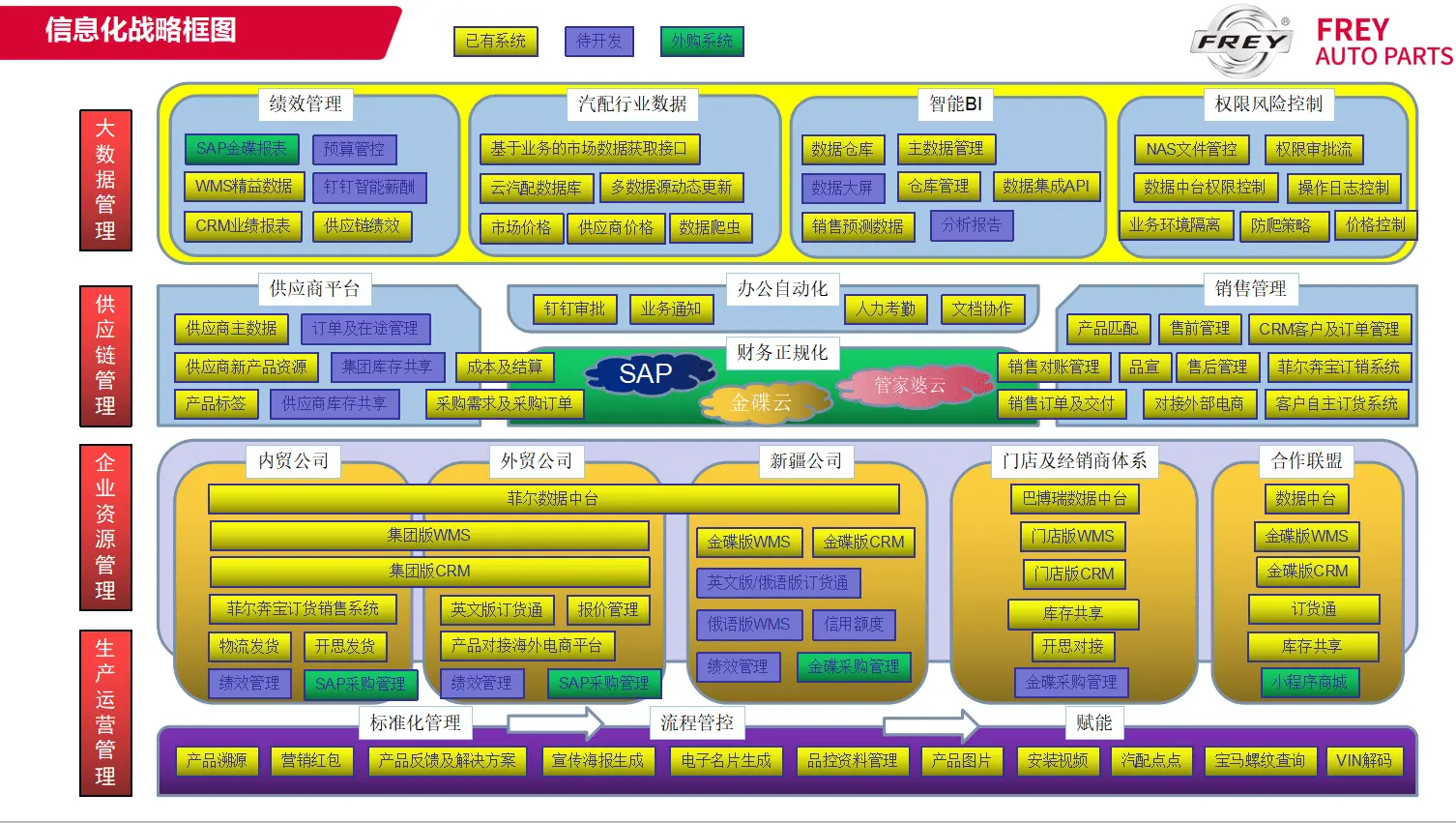

By introducing the one-stop management platform independently developed by Guangtui Technology, which includes "ERP+ data middle platform +CRM sales management system + Point Warehouse WMS warehouse management system +EC e-commerce sales system", and integrating it with SAP and Kingdee financial systems, Phil has achieved online digital and intelligent control of the entire business process. And the information-based integrated management of multiple companies/warehouses.

2. Sales orders generated by the sales system and purchase orders generated by the purchasing system can be directly pushed down to the Diancang WMS warehouse management system to generate inbound and outbound orders, without the need for manual order preparation.

3. After the warehouse staff complete the inbound and outbound orders in the Diancang WMS warehouse management system, the system can automatically write back the data to the sales/purchase orders, and the business personnel no longer need to go to the warehouse site for verification.

4. Warehouses of various companies can directly transfer goods and then generate business documents in reverse.

5. The entire process from outbound, inbound, picking, quality inspection, recheck, packaging, boxing, shipping, inventory taking, goods transfer to return is carried out through PDA handheld devices for scanning operations. If the scanned products are incorrect, an error will be automatically reported, significantly reducing the error rate of manual operations.

6. Warehouse keepers can obtain orders that need to be processed in real time, view the progress of operations and various data statistics in real time, and make dynamic adjustments to the operation methods.

7. All operations can be queried and traced, making it convenient to find and locate problems.

8. It automatically generates the optimal picking route and recommends the best picking storage locations, greatly enhancing the picking efficiency.

9. It is possible to conduct inventory checks while working without the need to suspend production or business operations for inventory checks.

10. Labels, packing lists, box codes, shipping marks, etc. can be automatically generated according to business requirements. One-click printing is convenient and fast.

Online revenue

√ Increase inventory accuracy by over 20% √ Save over 30% of warehouse space

√ Shorten the delivery time by over 100% Save over 30 warehouse management staff

Save over 20 order-following staff